[Tutorial] : Automated Quality Inspection System Using AI & FAVORIOT

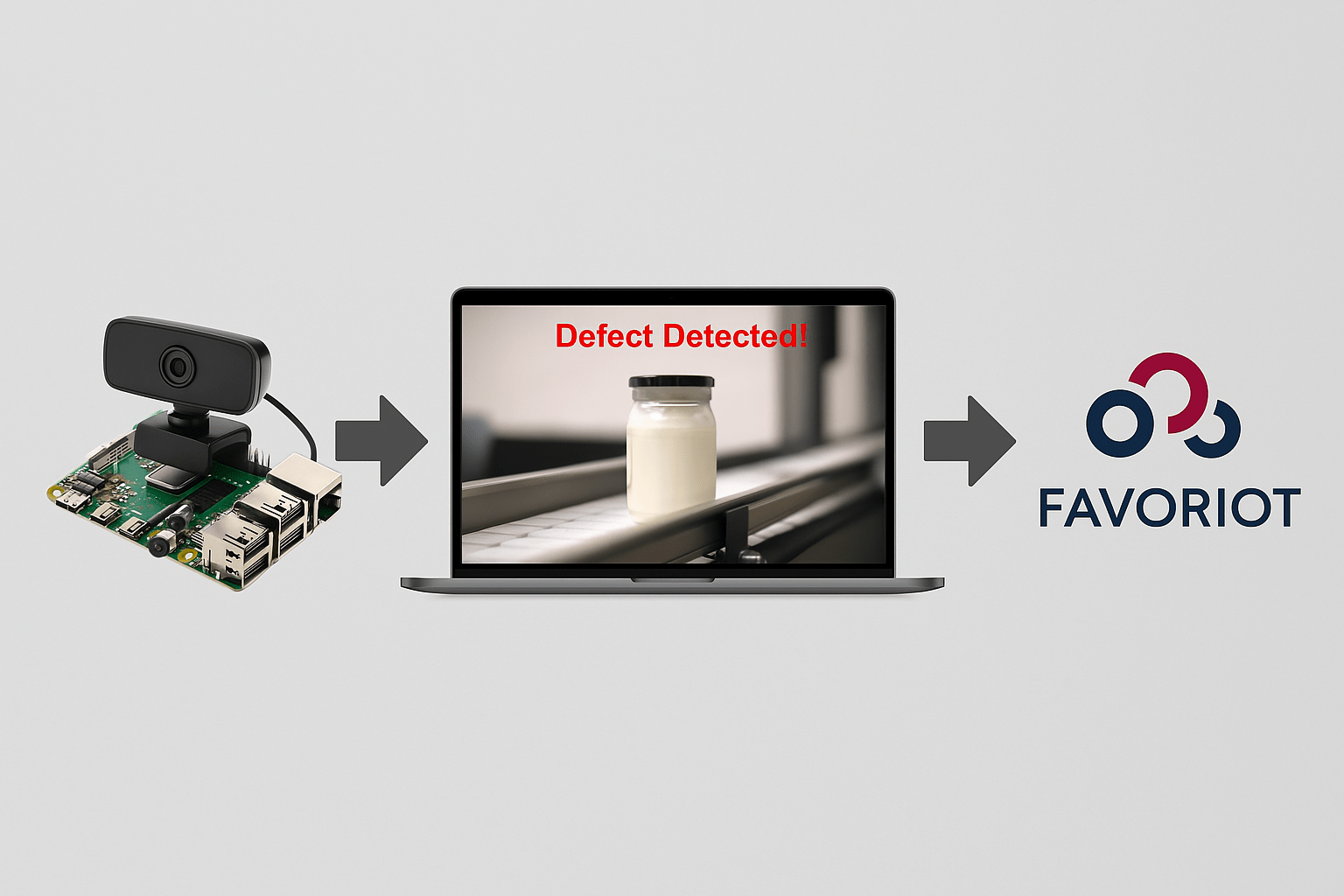

April 6th, 2025 Posted by favoriotadmin BLOG, HOW-TO, Internet of Things, IOT PLATFORM, TIPS 0 thoughts on “[Tutorial] : Automated Quality Inspection System Using AI & FAVORIOT”This guide will show you how to build an AI-powered quality inspection system using a camera and send inspection results to the FAVORIOT IoT platform in real time.

🔧 Step 1: What You Need

Hardware:

- Raspberry Pi (or any computer with a camera)

- Camera (USB or Pi Camera)

- Internet connection

Software:

- Python 3

- Libraries:

opencv-python,tensorflow,numpy,requests

🛠️ Step 2: Install the Required Software

Open Terminal and run:

sudo apt update && sudo apt upgrade -y

sudo apt install python3-pip -y

pip3 install opencv-python numpy requests tensorflow

🧠 Step 3: Train an AI Model to Detect Defects

Create a folder called dataset_defects with 2 subfolders: defect and normal.

Now, use this Python code to train the model:

import tensorflow as tf

from tensorflow.keras.preprocessing.image import ImageDataGenerator

dataset_path = "dataset_defects"

batch_size = 32

img_size = (224, 224)

datagen = ImageDataGenerator(rescale=1./255, validation_split=0.2)

train_data = datagen.flow_from_directory(

dataset_path,

target_size=img_size,

batch_size=batch_size,

class_mode="binary",

subset="training"

)

val_data = datagen.flow_from_directory(

dataset_path,

target_size=img_size,

batch_size=batch_size,

class_mode="binary",

subset="validation"

)

base_model = tf.keras.applications.MobileNetV2(input_shape=(224, 224, 3), include_top=False, weights="imagenet")

base_model.trainable = False

model = tf.keras.Sequential([

base_model,

tf.keras.layers.GlobalAveragePooling2D(),

tf.keras.layers.Dense(1, activation="sigmoid")

])

model.compile(optimizer="adam", loss="binary_crossentropy", metrics=["accuracy"])

model.fit(train_data, validation_data=val_data, epochs=10)

model.save("defect_detection_model.h5")

🎥 Step 4: Real-Time Defect Detection Using Camera

Once the model is trained and saved, run this script:

import cv2

import numpy as np

import tensorflow as tf

model = tf.keras.models.load_model("defect_detection_model.h5")

cap = cv2.VideoCapture(0)

while True:

ret, frame = cap.read()

if not ret:

break

img = cv2.resize(frame, (224, 224))

img = np.expand_dims(img, axis=0) / 255.0

prediction = model.predict(img)[0][0]

label = "Defect Detected!" if prediction > 0.5 else "Product OK"

color = (0, 0, 255) if prediction > 0.5 else (0, 255, 0)

cv2.putText(frame, label, (50, 50), cv2.FONT_HERSHEY_SIMPLEX, 1, color, 2)

cv2.imshow("Quality Inspection", frame)

if cv2.waitKey(1) & 0xFF == ord('q'):

break

cap.release()

cv2.destroyAllWindows()

🌐 Step 5: Send Defect Results to FAVORIOT

✅ 1. Set Up a Device in FAVORIOT

- Log in to Favoriot Platform

- Go to Devices → Add Device

- Note down your Device Developer ID and API Key

✅ 2. Add Code to Send Data

Below is the function to send results:

import requests

import json

DEVICE_ID = "YOUR_DEVICE_ID"

API_KEY = "YOUR_FAVORIOT_API_KEY"

URL = "https://apiv2.favoriot.com/v2/streams"

def send_data_to_favoriot(status):

payload = {

"device_developer_id": DEVICE_ID,

"data": {

"status": status

}

}

headers = {

"Content-Type": "application/json",

"Apikey": API_KEY

}

response = requests.post(URL, data=json.dumps(payload), headers=headers)

print("Response from Favoriot:", response.json())

✅ 3. Combine with Real-Time Detection

Add this snippet inside your prediction logic:

if prediction > 0.5:

send_data_to_favoriot("Defect Detected!")

else:

send_data_to_favoriot("Product OK")

📊 Step 6: View Data on FAVORIOT Dashboard

- Go to your device on the FAVORIOT Dashboard

- Click on Streams to view defect data

- You can also create graphs or alert rules for monitoring

🚀 Bonus Tips

- Add Telegram Alerts using Telegram Bot API

- Add Dashboard Charts using Favoriot’s visualization

- Improve accuracy with better dataset or model tuning

✅ Summary

With this project, you have:

✅ Built a real-time defect detection system

✅ Displayed results on screen

✅ Sent reports to FAVORIOT cloud platform

References

- Favoriot Platform Registration (FREE and Paid)

- Favoriot Full Documentation (Official)

- Favoriot Github

- How-To Use Favoriot Platform Video Playlist

Disclaimer

This article provides a step-by-step guide and only serves as a guideline. The source code may need adjustments to fit the final project design.